Epoxy Resin Cast Medium Voltage Instrument Transformers

Fibre & Fibre Glass Products designs and manufactures Epoxy Resin Cast CT's and PT's upto 33KV in its unit in Vadodara. Fibre & Fibre has facility of in-house fabrication, Painting and Testing.

FIBRE AND FIBRE GLASS PRODUCTS, DESIGNS THE TRANSFORMERS AS PER CUSTOMER REQUIREMENTS

Application :

Role of Instrument Transformers in electrical systems is of great importance as they are the means of stepping down current and voltage to measurable values. Secondary current and voltage is of proportionately lower value to the primary current and voltage. Metering Cubical can thus be used with ammeters and voltmeters for the measurements of current and voltages and with relays for protection.

Basic Feature :

- To reduce primary current and voltage to a measurable value

- To protect electrical systems with the help of relays

- To reduce risk to humans by isolating measuring side from high Current / Voltage side.

Design Criterion

The primary winding of the CT is either made of copper rope, copper foil or copper bar. This depends on the mould and design.

The secondary winding consists of core made from CRGO (Cold Rolled Grain Oriented). Super enameled copper wire is uniformly wound on core with the help of toroidal winding machines.

The Current and potential transformers are Epoxy resin cast. All the mixing and pouring of resin and other chemicals are duly monitored and recorded."Hot-Casting" method is followed and is performed under vacuum.

The coil of Potential Transformer is first impregnated in vacuum impregnation machine. This is a disciplined procedure and is done by experts. After successful impregnation, the coil can later be used for complete casting of the Potential Transformers.

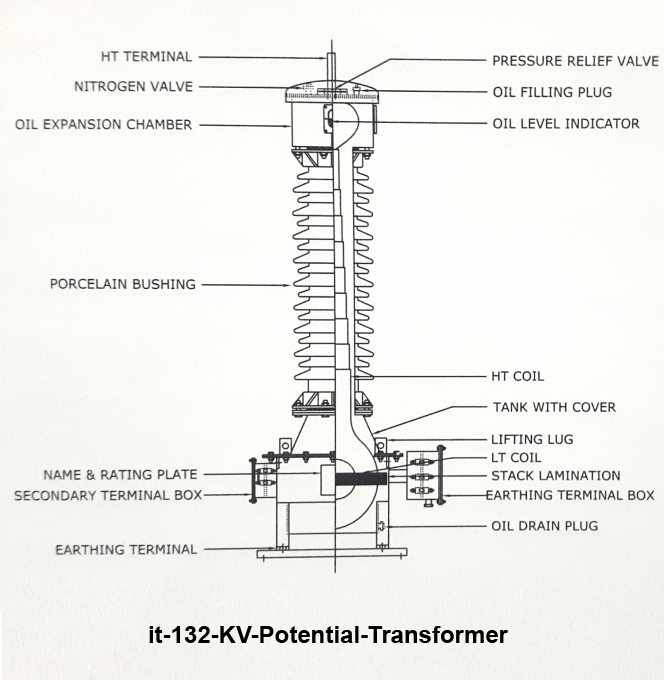

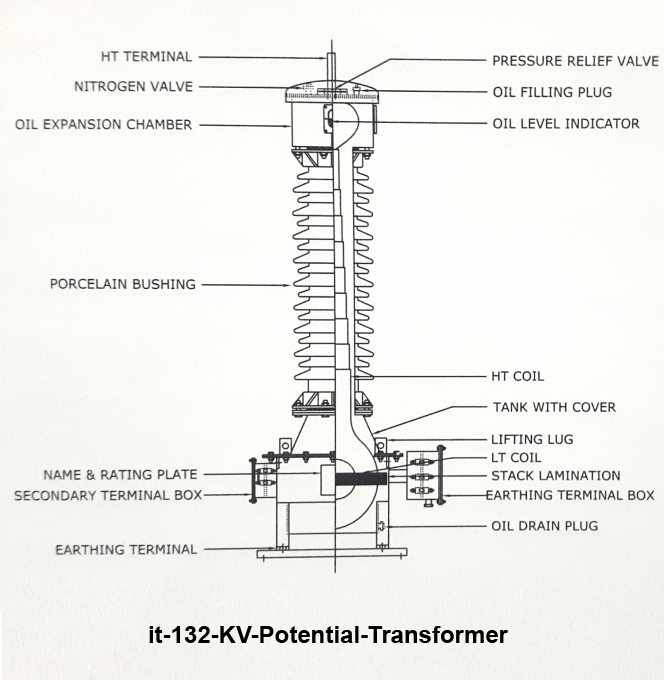

132 KV Potential Transformer

132 KV Potential Transformer

| ELECTRICAL CHARACTERISTICS OF CURRENT TRANSFORMERS (CONFIRMING TO IS: 2705 & IEC : 60044-1) |

|||

| TYPE: INDOOR, ERC | |||

| Nominal System Voltage (kv) | 11 | 33 | |

| Highest System Voltage (kv) | 11 | 36 | |

| Power Frequency withstand voltage 1 Min (kv) | 11 | 70 | |

| Impulse withstand voltage (kvp) | 11 | 170 | |

| Rated Burden | 2.5 VA TO 30 VA | ||

| 2.5 VA TO 30 VA | 50 Hz | 50 Hz | |

| Creepage Distance Phase to Earth (m.m.) | 300 | 900 | |

| Rated Primary Current (Amp.) | 5 Amp. to 2000 Amp. | ||

| Rated Continuous Thermal Current (Amp.) (Max) |

125% of rated primary current | ||

| Rated Secondary Current (Amp.) | 1 Amp. To 5 Amp. (or as per customer requirement) |

||

| Rated Short Time Thermal Current | 3KA TO 40KA for one/three second. | ||

| Rated Dynamic Current (KA-Peak) | 0.2s times of short time current. | ||

| Accurate Class (IS/IEC Standard) | 0.2s (Min.) for Metering & 5P, 10P & PS for Protection |

||

| Rated Instrument Security Factor | 5 | ||

| Rated Accuracy Limit Factor | 10, 20, 30 | ||

132 KV Potential Transformer

132 KV Potential Transformer

| ELECTRICAL CHARACTERISTICS OF POTENTIAL TRANSFORMERS (CONFIRMING TO IS: 3156 & IEC: 60044-2) |

|||

| TYPE: INDOOR, ERC | |||

| Nominal System Voltage (kv) | 11 | 33 | |

| Highest System Voltage (kv) | 12 | 36 | |

| Power Frequency withstand voltage 1 Min (kv) |

28 | 70 | |

| Impulse withstand Voltage (kvp) | 75 | 170 | |

| Rated Burden | 10 VA TO 500 VA | ||

| Rated Frequency (Hz) | 50 Hz | 50 Hz | |

| Creepage Distance Phase to Earth (m.m.) |

300 | 900 | |

| Rated Secondary Voltage | 110 volt, 110/v 3 volt | ||

| Rated Voltage Factor | 1.2 cont. & 1.5 cont for 30 second. | ||

| Accuracy Class (IS/IEC Standard) | 0.2, 0.5, 1.0 for metering & 3P, 5P, 6P for protection | ||